B03+3

《基于现代供应链的——采购策略与谈判技巧》

Training Course Outline

The Procurement Strategy and Negotiation Tactics

Based on the Advanced Supply Chain

Directions:

1. This outline takes full consideration to the customer requirements and the course could be adjusted according to the detailed feedback information from the customers.

2. Based on the ways of process thinking, the course is the interpretation to the advanced supply chain management, operation, integration, coordination and optimization where we go for all efforts to establish and strength the global procurement process. The course aims to support the customer to run business relying on the procurement process and the relevant technique and skills, instead of the sophisticated staff.

3. The outline and the PPT used in classroom are mainly in English and the training is given mainly by English.

4. A typical page of PPT shared as below and we already give this course to the China Aviation Lithium Battery Co., Ltd successfully where an excellent team we met that supplies the components in heavy machinery of the China aircraft carriers.

Background:

With the rapid development in the change era, The level and ability to the supply chain management will become the important indicators to measure the core competitiveness of companies. Companies need to develop the substantial procurement strategy, procurement process, and supplier management and negotiation tactics according to its own business situation, to gain the competitive advantage. Based on the theory of modern supply chain, combined with the management and operation experience in the world top 500 giants, we recommend this course in field.

Trainees:

GM, VGM, COO, finance director, supply chain director, procurement director, logistics director, manufacturing manager, procurement manager, project manager, logistics manager, other relevant managers and core staff to the supply chain.

Goals:

This course introduces in detail the procurement Strategy and negotiation tactics based on the advanced supply chain basic theory, and combined with the operating best practices, to put series of solutions, tools and techniques in an organic whole. The Trainees will benefit from the course as following:

1. Be aware of and understand the patterns and characteristics of supplier management and the relationship maintenance, and to the basic methods and skills.

2. To understand the procurement and negotiation strategy, tactics and skills, and to be able to use skillfully.

3. To the basic skills of purchasing to improve the procurement business efficiency and effectiveness continuously. Get the ability to lead an improvement project to get things down.

Timing:

18 class hrs (6 Class hrs/day)

Detailed Content:

[Warm-up]

►Self-introduction

►David(达飝) training approach —Learning by Doing, Learning by cases.

►Unyielding Principle in manufacturing field.

►Along the way of traditional, lean, agile management,

we are going into a new era……zoujin走进

►The Combination of theory and practice.

►The Language misunderstanding and mine field.

►Win in the ways of thinking – Dive into deep water area of our business.

Fish-bones diagram (cause and effect diagram) re-understanding

Performance management (indicators) re-understanding

SWOT re-understanding

8D report re-understanding

"Smiling curve" re-understanding

[Icebreaking]

►The different ways of thinking habits to business management

between the East and West.

►The Iceberg theory is cash? or promissory note, or a bounced check?

►The most active "invisible killer" in our business – the document

PART 1 Necessary & Essential management skills

1.1 The world top 500 internal training - The different ways of thinking

habits to business management between the East and West.

1.2 Awareness of a modern manager - what is the process?

1.3 Awareness of a modern manager - what is "Go Techniques"?

2.4 Bottleneck Operation - process in the processes

2.5 The non-financial costs

2.6 Decision "Iron Triangle" - Pick-Any-Two

2.7 Concurrent Engineering

2.8 Contingency Management

2.9 Watch out for the difference between ICS and CCS,

strengthening the standardization Engineering

PART 2 Necessary & Essential professional skills

2.1 Working with People

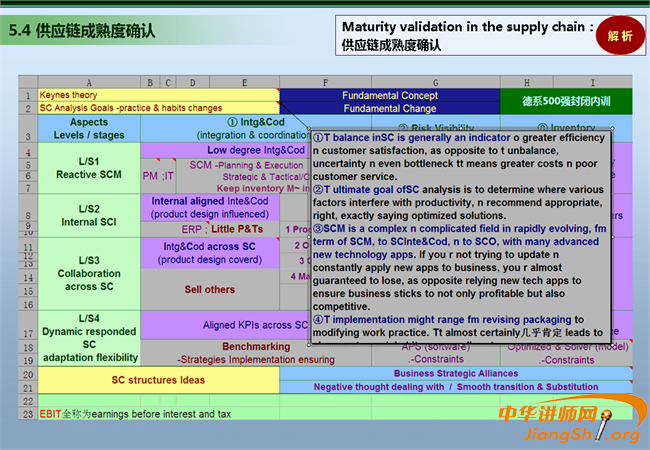

2.2 Keynes Theory - Supply and Demand Theory

2.3 Implementing IT (Information Technology) Systems.

2.4 Utilizing the best software – PM, ERP & SCM.

2.5 Supply Chain Analysis Goal

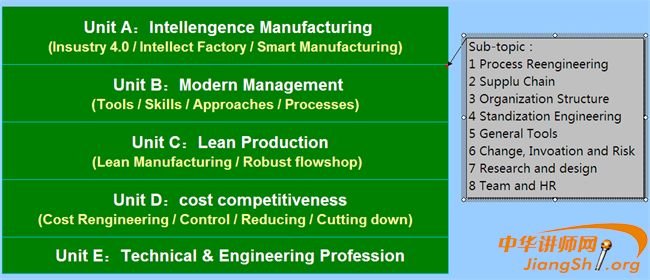

PART 3 Advanced Supply Chain

3.1 Supply Chain Management

3.2 Supply Chain Business Integration

3.3 Supply Chain Business Coordination

3.4 Supply Chain Optimization - holistic Optimization

3.5 Supply Chain Optimization - Best solution

3.6 Supply Chain Optimization - Three Keys to Effectiveness

3.7 Supply Chain Maturity - Four Levels

3.8 Experiences to Attention

PART 4 Supply Chain substantialzing & Strengthening

4.1 The strategy and execution

4.2 The intelligence and counterintelligence

4.3 The IT platform and information

4.4 The risk decision, control and management

4.5 The excellent manufacturing site

4.6 The advanced financial system

4.7 The modern HR system

4.8 The R&D engine lubrication

4.9 The advanced organization structure

4.10 The legal items

PART 5 Interaction, Discussion and Encouragement

-end-

---------------------------------------------------------------------------------------------------------------

David(达飝) Famous Enterprise Training

Director of Institute on China Intelligent manufacturing

Director of Institute on Change and Innovation Engineering

Over 20 years career in world top 500.

— 10 years in western giant manufacturing group

— 10 years in China state-owned weaponry group

The amphibious management experience between the east and the west.

PROCESS AND TOOLS ORIENTED

Over 60,000 people have been trained

Background:

10 years of CEO/plant manager in Magna International Group, Winkelmann GmbH.

and other MNC.

10 years of executive in top management in CNIGC (China North Industries Group).

Highlight:

Plentiful management experience during the change period. Solid experience on site. Senior technical and engineering background.

Be fond of and good at getting down actual issues in clients.

Benchmark achievement:

1 Took charge of the chassis components verification test for armored vehicles served for the China National Day Parade. Final-sign the state inspection report. Won praise from client division in army.

2 Won excellent performance in western world top 500s, market developed, revenue boosted and team uplifted.

3 Lead the audit to the David fund of the automobile vibration and damping.

4 Supported many clients in industry area to achieve cross-industry monopoly, along with providing the necessary training timely. The first person in current China who practice to “make difference in financial statement” as a lecturer in consultation area.

Education background:

Combined bachelor of Business Administration and Environment Chemistry Engineering.

of Business Administration. MBA plus.

Management Skills in details:

GPMS, GAAP, IFRS, Matrix organization, APS, QAD(ERP), ISO9001, ISO/TS16949/ VDA; ISO14001, OHSAS18001; QC tools (APQP, PPAP, FMEA, SPC, MSA) & 6σ along with lean experience on site. DfMAS, SCM, Supply chain coordination, integration & optimization. German/Italian engineering drawing understanding. EHS and Chinese Labor Contract Law. Knowing the way of thinking and doing things of Chinese team, customers and local government.

Engineering Experience in details:

Products and processes ever led: forging n casting; machining; welding including friction stir welding; stamping n punching especially roll-forming n spinning; surface treatment covering painting n e-coating, heat treatment, high frequency quenching; plastic products; rubber products n process; plastic/rubber combined with metal working assemblies; in-tools process improving n customizing in fashion industry and steel tube cleaning field, and the automatic integrated units/devices/machines/equipment joint performance testing n evaluation on site.

Strong point in training and courses:

1 The world top 500s knowledge, skills and experience.

2 To dissect business blind, wrong and dead zone in ways of structural type, to push business actions in ways of process type as the shared results.

3 To share cross level example cases in recent years, along with specific games in classroom.

4 To strive to “make difference in financial statement”, of, with and by discussion and analysis to the actual cases from clients.

David’s viewpoint:

Based on the huge lessons and the marvel performance, just as said out by the German teacher Dr. Christopher:

We can not divide business activities in to short term and long term. In a sense the short interest be the long interest, the reverse is also true. Any long term business action without the short tern interest is nothing but building the bridge for the competitors.

David's Main Courses List

To share with you:

Learning by Doing and learning by Sample.

David’s Team in world top 500s included: Korea logistics and warehouse officers; American, Canadian, Japan equipment experts; Australian project management expert; Russia engineers and experts; Indian QC and SQE officers; Malaysian risk management expert; Singapore training experts; Vietnam and Cambodian skilled technicians.

Typical Clients Served:

---------------------------------------------------------------------------------------------------------------------------------

达飝咨询教练团队介绍

达飝咨询教练团队,针对当今供给侧改革制造企业特别组建,为地方政府责任官员和追求卓越的大中小制造企业量身定制。

强悍地助推制造企业,践行创新变革、转型升级、破题突围、弯道超车!

团队老师都来自企业,从基层做起,都有跨国世界500强、或制造业企业级一把手经验阅历,谙熟制造现场与企业团队。

个人一线单兵实战功底雄厚。

● 有的在车间手摸被试件估测温度能精确到0.1℃;

(话外音:熟练显示水平!您可以想象,这位老师在车间一线要手摸多少次被试件后,才能够达到如此熟练程度。)

● 有的几乎熟记《机械手册》常规机械尺寸系列与公差参数;

(话外音:海量工作显示水平!这绝不是刻意背诵《机械手册》。您可以想象,这位老师在研发与设计一线,要画出过多少张图纸,才能达到如此“熟记”境界。)

● 有的能够在电脑里“手抓病毒(直接读源代码判断和删除病毒)”, 从不使用杀毒软件;有的拥有德国温泽μ级CMM培训师资质;有的是美国AutoDesk中国首批授权培训师;

(话外音:每位老师都拥有高度专业的个人拳头技能。)

● 有的曾在自己旗舰组装车间当场抓住日本工程师(日本东机工株式会社)非法拍照;日本工程师承认盗窃拍照并请吃饭“谢罪”;

(话外音:每位老师都拥有自己平凡朴实的一线现场实战业绩。)

● 有的在保时捷特训营获(国际)三级赛车手证书、考试科目之一是驾车越野“撞死飞鸟”;有的进入全国高校游泳锦标赛前八名、有的通过国家体操三级(业余)运动员考试……

(话外音:每位老师都有自身较强的操作动手能力。)

● 有的通晓三种语系语言。亚洲语言(中文,日语)、欧美语言(英语,德语,法语)、阿拉伯语言(阿拉伯语,波斯语)。同时,还具有飞机制造高级工程师资质。

(话外音:每位老师都站在全球化视角,品味企业管理、品读企业课题。)

… … …

达飝团队全部是海外或国内主流大学,硕士以上学历,厚重的专业工程技术功底与个人固有资质技能、可以实现与制造企业密切的产品级、技术级无障碍沟通和对接。

达飝团队都是中国本土企业成长的见证者。对中国本土文化、中国企业架构,决策流程、中国员工人际关系充分了解,

立足中国传统文化背景,展望全球行业变革创新态势、输出专题专项咨询。

达飝特训咨询直接发力于企业实战。务实落地的实施方法,能帮助您的企业少走弯路,迅速提升业绩。达飝团队践行“软科学硬化”智能制造时代新潮流,

与您同步,追逐的目标,是改变企业当期财务报表显示!

Make Diffidence to Financial Statement!

浙公网安备 33010802003509号

浙公网安备 33010802003509号